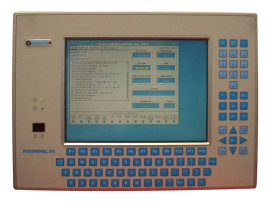

THE INDUSTRIAL SOFTWARE SUPERVISOR SYSTEM MODEL OMI-FULL

OMI-FULL HAS SIX ( 6 ) IMPORTANT SUPERVISOR CHARACTERISTICS :

IT’S A LAST GENERATION TOUCH SCREEN TERMINAL THAT ALLOWS VISUALIZATION AND CONTROL OF ALL MACHINE FUNCTIONS..

- MONITORING AND MANAGEMENT OF THE RECIPE THAT EXECUTED;

- MONITORING OF MACHINES PARAMETERS ( SPEED , TEMPERATURE, QUANTITY OF WATER, ETC. );

- TREND OF TEMPERATURE WITH HISTORICAL DATA;

- SYNOPTIC OF HYDRAULIC AND PNEUMATIC MACHINE FUNCTIONS;

- TEST INPUT/OUTPUT THAT ALLOWS IMMEDIATELY A DIAGNOSIS OF THE BREAKS;

- SYNOPTIC OF THE PLANNED MAINTENANCE OF THE MACHINE.

The machine recipe is edited and stored in a database that resides on the master PC of system ( this avoid the problem of data inconsistency ) , the master pc also provide the automatic delivering of recipes when tha machines requests them.

You can make a previous plan of productions that you want to work also giving them a priority to plan the productions .

The production manager must assign the machine’s recipes to the goods, also he must give other informations that identify the goods path relatively to the working method ( for example the white clothing can be send to the machine that usually make white works and the same can be done for particular processig requirements that you can have). Naturally the system allows to have a history of this data and so you can post-monitoring the real path that the goods has made to analyse it.

The supervison system structure allows, with the only requirement of a high speed internet connection ( xdsl , will suffice ) to have an assistance from the OMI.

The same method is used to give the possibility to a production manager to control , the processing status of the goods and calculate the delivery time.

To make that the production manager does not have to contact the plant manager but he can consult this data easily from any remote office.

The supervisor sistem is able to notify all operations that are made by machines so if you first specify the cost of a single operation you can have the possibility to know the amount of cost to process a single clothing.

The system is also able to communicate with a large number of products dosing sistems thus guaranteeing the products supply when the machine requires them.

If the products dosing system does not use standard protocols of communications we can make a personalized program on a embedded microprocessor card to interface the different systems.

———————————————————–

English

English Italian

Italian French

French